Big data, machine learning, product digital twins and predictive maintenance—is it all only about marketing buzzwords or there is something real going on behind them? Industry 4.0 is becoming more and more tangible, but not everyone by far can realize what it is going to look like in the near future. At the same time, it is clear that this is something to come true in all industries—most likely, through an evolutionary process.

There are many articles in virtually all industrial magazines about Industry 4.0 and the problems it is supposed to address, so avid readers can easily google it. In this small article, we would like to share our experience and vision of the technologies that might help solve the problems.

Data science. How is it connected to Industry 4.0?

Why the big data concept, along with its analytical methods, is so important for the implementation of Industry 4.0? To make a factory smart and self-sufficient, it needs to be trained; and we need to take advantage of the best machine learning practices used in the manufacturing processes. The main purpose of machine learning is to develop algorithms that make predictions based on data. The algorithms/methods adaptively improve their performance as long as the number of learning samples increases; and that is why the accurate data becomes crucial.

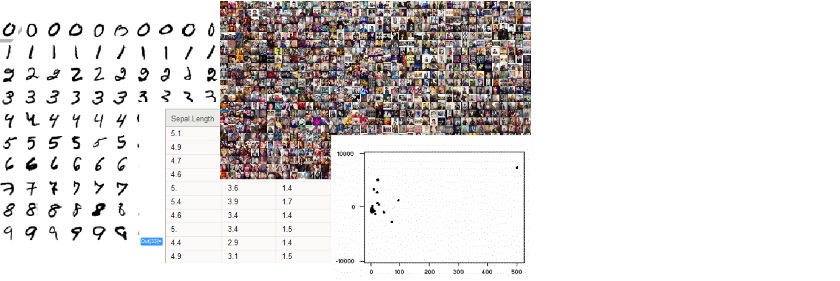

What is the data then? It is a set of grouped metrics describing the properties of an object. Everything is data if you look close enough:

And what are the methods? Surprisingly, some methods have already been in place for a few centuries. Fundamental mathematical methods to solve such machine learning problems as data clustering, classification and regression were reported by scientists in 19th and 20th centuries already. Linear regression based on least squares is a good example introduced by Gauss in 1809. The absence of accurate and sufficient data used to prevent any learning experience for a long time. Now, thanks to the Internet of Things developments and the availability of modern and powerful IT infrastructures, we have gained the possibility to collect more and more data about manufacturing processes.