Why Worker Guidance Matters

Clear and intuitive guidance systems reduce human errors, improve training outcomes, and increase output. Our solutions make it easy for operators to follow critical steps, adjust in real time, and track progress — all while interacting with machines and processes.

What We Deliver

We help teams implement systems that:

- Guide operators through complex procedures, step by step

- Validate actions and prevent mistakes (Poka‑Yoke)

- Display dynamic instructions linked to specific stations or workflows

- Integrate directly with PLCs, MES, ERP, and control units

- Support both desktop and touchscreen HMIs

- Enable error logging and quality traceability

- Deliver training-on-the-job and adaptive support

Success Stories

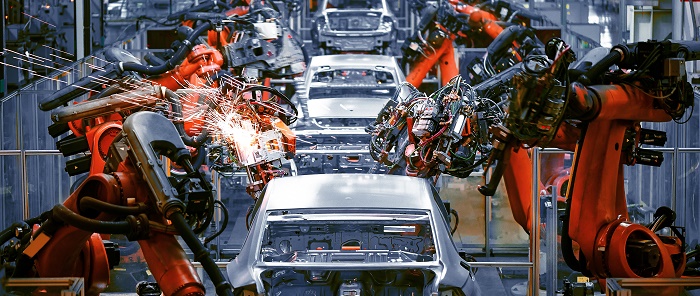

Assembly Support for Automotive Clients

We integrated worker guidance into an automotive assembly line — offering real-time step prompts, quality checkpoints, and streamlined machine interaction. The result: fewer stoppages and better productivity.

Smart Manufacturing Instructions

In complex production setups, we built a digital instruction system that retrieves job-specific guidance at each station, tracks progress, and logs deviations — enabling quick onboarding and fewer mistakes.

Multi‑Stage Process Tooling

For clients running multi-step manufacturing, we deployed HMI-guided steps that validate each operation via MES integration, ensuring compliance and consistent quality across shifts.

Behind the Screens

- Rule-based sequencing: Procedures adapt based on prior step results

- Machine-status awareness: Guidance adjusts to real-time signals from PLCs or sensors

- User logging and auditing: Full records of who performed what action, when, and how

- Flexible UI: Designed for both fixed HMIs and mobile or tablet-based interfaces

Why Choose GRSE

- Software experts who understand physical workflows

- Seamless integration — both human and machine context included

- Hands-on experience in regulated sectors: automotive, foodtech, pharma

- Fast delivery: from prototype to rollout in weeks

- Continuous improvement: from feedback loops to updates

When to Invest in Worker Guidance

- Errors are expensive or unsafe

- Training time is long or frequent

- Quality demands are high and manual mistakes cause delays

- You want to improve onboarding, traceability, and process control

Ready to Guide Your Operators Better?

Let’s design a guidance system that reduces errors, speeds up training, and supports your team in real time.